### Core Functions of Hydraulic Gearboxes

Hydraulic gearboxes are essential for converting mechanical energy into hydraulic energy, facilitating torque conversion within hydraulic systems. Based on Pascal's Law, this process operates under the principles where pressure applied to an enclosed fluid transmits force equally in all directions. This allows for the multiplication of torque, which enhances the system's performance across various applications such as construction and manufacturing. Evidence shows that employing hydraulic gearboxes in these settings can significantly improve operational efficiency and effectiveness by allowing heavier loads to be managed with reduced mechanical input.

The gearing mechanisms in hydraulic gearboxes are crucial for effective power transmission. By leveraging different gear ratios, these systems ensure optimal power distribution across the desired operations. Common gear types utilized in these mechanisms include planetary and spur gears, each contributing to system efficiency and performance. For instance, planetary gears are renowned for their compactness and load distribution capabilities, which translate to better overall efficiency. In industrial scenarios, optimally designed gearing mechanisms in hydraulic gearboxes have been shown to enhance machine performance, reduce wear and tear, and increase productivity.

In heavy machinery applications, hydraulic gearboxes are indispensable, offering the power necessary for effective load handling. They enable equipment to lift and move substantial loads efficiently, often determining the machinery's operational capability. Discussions around load ratings and hydraulic efficiency reveal that gearboxes in these systems are designed to meet rigorous industry standards, ensuring reliability and performance under demanding conditions. Standards such as ISO 281 provide guidelines for load handling capacity, affirming the gearbox's capacity to sustain its function over extended periods, thereby establishing hydraulic gearboxes as a benchmark in heavy machinery applications.

Compatibility between hydraulic gearboxes and gear pumps is essential for creating efficient hydraulic circuits. Gear pumps, such as external gear pumps, mesh seamlessly with hydraulic gearboxes to enhance performance. These pumps play a crucial role in pressurizing liquids within hydraulic systems, allowing for the efficient transfer of energy. Studies show that optimized gear pump integration can lead to improved flow rates and overall circuit efficiency. For instance, performance tests indicate that hydraulic circuits with well-matched gear pumps and gearboxes achieve superior mechanical output, highlighting an effective synergy.

Engine oil pumps are key to optimizing fluid flow within hydraulic systems, particularly by lubricating hydraulic gearboxes. Proper lubrication is critical for maintaining operational efficiency and extending the lifespan of hydraulic gearboxes. By analyzing fluid dynamics, manufacturers can develop methodologies to optimize fluid flow through these systems. An example from the industry shows that integrating engine oil pumps has led to significant improvements in efficiency and durability. These pumps ensure continuous fluid circulation, minimizing friction and wear within the gearbox, ultimately enhancing the system's performance and reliability.

The integration of hydraulic gearboxes in pressure regulation mechanisms is crucial for hydraulic ram pumps. Proper pressure regulation is vital for ensuring the safe and efficient operation of these systems. By maintaining optimal pressure levels, hydraulic gearboxes enhance the performance and safety of hydraulic ram applications. Case studies illustrate the benefits of effective pressure management, showing increased operational efficiency in hydraulic systems. These systems leverage power from hydraulic gearboxes to manage pressure changes, allowing for precise control in various industrial and construction applications.

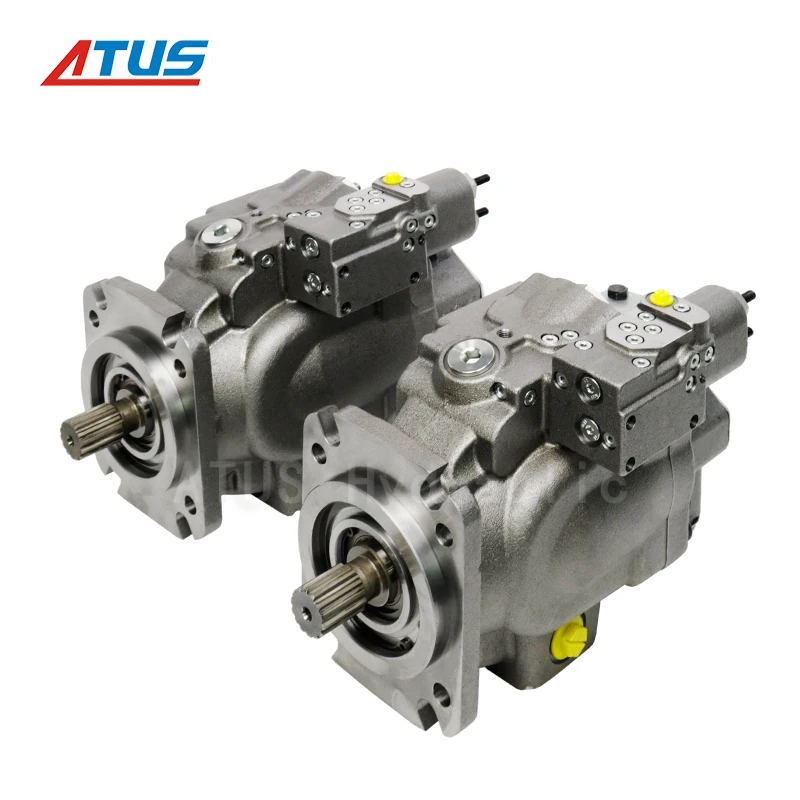

The P2/P3 double plunger pump is a high-performance solution tailored for roadheaders, delivering exceptional high-pressure hydraulic output essential for mining and tunneling applications. This pump is designed with advanced features that cater to the demanding conditions of industrial environments. By employing a double plunger design, it ensures consistent and reliable performance, making it indispensable for heavy-duty tasks such as rock cutting and material excavation.

In terms of operational advantages, the P2/P3 pump offers substantial flow and pressure capabilities, critical for effective tunneling. It provides precise control over hydraulic performance, ensuring minimal disruptions to operations and contributing to increased safety and productivity measures. Field performance statistics underscore its benefits, with users reporting significant improvements in system reliability and efficiency under intense workload conditions.

Piston pumps are vital components in mining machinery, ensuring unmatched reliability and efficiency, even under harsh and abrasive conditions. They are designed to withstand demanding scenarios, making them indispensable for machinery that operates continuously. The Parker Piston Pumps Set, particularly models P2145 and P2105, exemplify robust design and advanced pump technology that ensure optimal performance.

The models' specifications indicate their superior output capabilities, essential for the continuous operation requirements of the mining industry. Data-driven evaluations reveal that these piston pumps offer enhanced performance flexibility and resilience, providing a competitive edge in productivity and reliability in mining operations.

The F12-030 hydraulic feeder motor is an integral component for mobile impact crushers, guaranteeing smooth and efficient operation critical for optimal crushing output. This hydraulic motor is engineered to withstand rigorous conditions, providing exceptional torque and consistent speed for continuous, high-demand functions within the crusher’s hydraulic system.

Highlighting the F12-030 motor’s attributes, it stands out for its rugged construction, advanced hydraulic technology, and compact design, facilitating easy integration. Performance metrics and manufacturer specs highlight its capacity to significantly boost crusher throughput, making it an essential component in enhancing operational efficiency in construction and mining settings.

Selecting the right hydraulic fluid is vital for maintaining the performance and longevity of gearboxes. Hydraulic fluid acts as a lubricant, reducing friction and wear within the gearbox, thereby extending its lifespan. To choose the optimal fluid, you must understand the unique properties of various fluid types, such as their viscosity, thermal stability, and corrosion prevention capabilities. For instance, studies show that fluids with higher viscosity are beneficial in high load applications, while those with superior thermal stability are preferred in environments with fluctuating temperatures. Furthermore, research has consistently demonstrated that fluid choice directly impacts gearbox wear rates, underscoring the importance of careful selection.

Regular pressure threshold checks in hydraulic circuits are essential for ensuring system integrity and preventing failures. Hydraulic systems operate under the principles of Pascal's Law and Bernoulli's Principle, which dictate fluid movement under pressure. To maintain system efficiency, maintenance teams must conduct systematic checks, identifying potential pressure variations that could compromise the hydraulic circuit's function. Documentation of these procedures, including specific actions to be taken in case of anomalies, provides a valuable reference guide to teams. Statistics often reveal significant system downtimes occur due to neglected pressure checks, highlighting their critical role in minimizing disruptions.

Conducting a wear analysis on hydraulic pump components is crucial for preemptive maintenance and avoiding potential failures. Hydraulic pumps, including types like piston, gear, and vane pumps, experience various wear patterns based on operational conditions. Diagnostic techniques, such as vibration analysis and thermography, offer valuable insights into pump health, allowing for timely interventions. Industry reports consistently show that wear analysis significantly reduces maintenance costs by identifying issues before they escalate. This proactive approach ensures hydraulic systems function smoothly, maintaining operational efficiency and preventing costly repairs. Integrating wear analysis into routine maintenance plans is a strategic move for anyone using hydraulic systems.