Rotors are crucial to the functionality of a vane pump, acting as the system's core component that initiates the transfer of fluid. When the rotor spins within the pump, sliding vanes attached to the rotor extend and retract. This ingenious mechanism allows the vanes to adapt to the contours of the pump body. By doing so, the vanes maintain a constant and tight seal, which is vital for effective suction and to ensure a steady flow of fluid. Understanding the dynamic interaction between the rotors and sliding vanes is key to appreciating the reliability and precision of vane pump mechanics. These components work in harmony to facilitate the movement of fluids under various operational conditions, maintaining efficiency in hydraulic systems and other industrial applications.

Eccentric rotation in a vane pump is critical for pressure creation. As the rotor turns in an off-center or eccentric manner, the chamber volumes within the pump change. These varying chamber volumes are essential for generating both pressure and suction, pivotal for the continuous flow characteristic of vane pumps. Unlike other pumps, the continuous flow ensures minimal pulsation, making vane pumps preferable in systems requiring smooth and constant fluid delivery. The ability of these pumps to maintain a consistent flow under varying pressure conditions differentiates them significantly from other pump types, such as hydraulic cylinder systems that may suffer from more significant pulsation issues.

The self-priming ability of vane pumps enhances their efficiency and operational readiness. This feature allows vane pumps to automatically draw fluids into the system without requiring manual intervention, a crucial advantage in scenarios where pumps are occasionally not submerged in fluid. This capability is particularly beneficial in applications where it’s essential to have prompt pump startup without manual operations, such as in certain mobile hydraulic systems or other environments where mechanical access is limited. By eliminating manual priming, vane pumps enhance system reliability and ensure that fluid delivery begins with minimal delay, contributing to their widespread use in diverse industrial sectors.

Vane pumps can be categorized primarily into fixed and variable displacement designs, each boasting unique benefits tailored for specific applications. Fixed displacement vane pumps deliver a constant flow of fluid with each rotor revolution, making them suitable for systems where a steady, reliable fluid delivery is crucial, such as in hydraulic presses or power steering systems. This fixed flow rate ensures stability and predictability in processes requiring uniform fluid transmission.

On the other hand, variable displacement vane pumps adjust their flow rates in response to varying load demands. This adaptability enhances system efficiency by minimizing energy consumption, especially in operations subject to fluctuating requirements. These pumps are integral to hydraulic systems that necessitate changing pressures and flows, offering a balance between performance and energy efficiency.

Rotary vane pumps excel in transporting low-viscosity fluids, making them ideal for industries like food and beverage. Their design allows for the efficient transfer of thin liquids without the risk of emulsification, preserving the integrity of sensitive fluids. This characteristic is particularly beneficial in processes that require gentle handling, such as transferring milk or oils, where maintaining texture and composition is crucial.

Moreover, these pumps ensure a smooth fluid flow, minimizing pulsation and turbulence, which can be detrimental in precision applications. Their efficiency and reliability make them indispensable in sectors that demand hygienic and consistent fluid transport, underscoring their versatile application potential.

Hydraulic vane pumps are foundational in heavy machinery, playing a pivotal role in industries such as construction and mining. Their ability to operate under high-pressure conditions makes them suitable for demanding tasks like operating hydraulic jacks or powering large-scale machinery. These pumps provide the hydraulic force necessary to drive heavy-duty equipment, ensuring smooth operation even under strenuous use.

The robust performance of hydraulic vane pumps in such environments not only enhances machine efficiency but also prolongs equipment lifespan by ensuring reliable and consistent power delivery. Their integration into industrial machinery underscores their importance in maintaining productivity and efficiency in operations requiring substantial hydraulic power.

Vane pumps play an integral role in CNC machining, particularly in precision fluid transfer tasks. Their ability to maintain consistent flow and pressure ensures effective cooling and lubrication during machining processes, safeguarding both the equipment and the quality of the machined parts. The precise flow control aspect of vane pumps is crucial, as it allows for the meticulous management of coolant distribution, directly impacting the efficiency and precision of machining operations. By providing stable lubrication, vane pumps help minimize wear and tear on cutting tools, thus extending their lifecycle.

In oil drilling operations, vane pumps are pivotal components within hydraulic power systems. These pumps provide essential energy for various drilling operations by managing high-pressure hydraulic fluids. Their robust design and capability to handle extreme pressure ensure the smooth running of drilling rigs, thus contributing to operational efficiency. Understanding how these pumps operate and their role in hydraulic systems is critical for ensuring the longevity and effectiveness of drilling equipment. Proper energy management facilitated by vane pumps not only enhances drilling operations but also helps in cost management by reducing equipment wear.

Vane pumps are indispensable in high-pressure fuel systems, where they guarantee a consistent delivery of fuel to engines, ensuring optimal engine performance. These pumps are equally critical in lubrication systems, where reliable fluid delivery is fundamental to machinery longevity. By maintaining steady pressure and flow, vane pumps prevent overheating and wear in engines and other mechanical systems, thereby enhancing reliability and performance. The constant and reliable flow of lubricants ensures that moving parts operate smoothly, reducing friction and thereby extending the operational life of equipment.

For more details on vane pumps, refer to THM Huade Hydraulics for product specifications and features suited to your industrial applications.

The Variable Vane Pump PV7, specifically designed for CNC boring and milling machines, excels in dynamic flow rate adaptation to enhance precision machining applications. This model efficiently adapts fluid transfer rates to support the precise requirements of CNC operations, ensuring smooth processes and high accuracy. Additionally, its compact design allows seamless integration within CNC setups, minimizing space usage and boosting overall productivity. The PV7 is highly regarded for its ability to maintain consistent performance without compromising on the efficiency essential in precision engineering tasks.

Hydraulic power system pumps are crucial components designed for oil rigs, promoting mobility and adaptability in demanding environments. These pumps are tailored to withstand the rigors of drilling operations, offering robust pressure management that ensures seamless equipment functionality. Vane pumps in hydraulic systems are instrumental in providing the necessary force, stabilizing operations even under high-pressure scenarios. This specialized design aids in operational precision, vital for maneuvering oil rigs and optimizing their movement capabilities, thereby maximizing efficiency and safety in energy management applications.

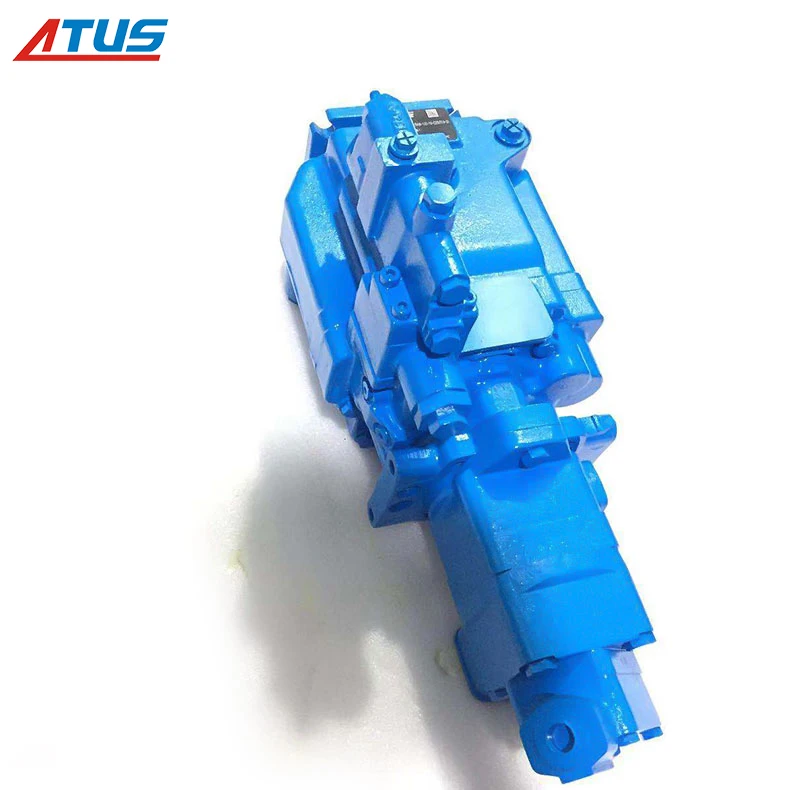

Vickers axial piston pumps stand out due to their robust designs optimized for extensive industrial applications, featuring configurations that bolster their adaptability in larger systems. These tandem setups enhance flow capacity, offering comprehensive solutions for fueling demanding operations with uninterrupted fluid transfer. The dual arrangement allows these pumps to deliver high efficiency and reliability, crucial for environments requiring sustained performance. With additional control features, Vickers pumps present fine-tuned operations, a preferable choice for industries prioritizing durable and efficient fluid handling systems.

Vane pumps stand out for their energy efficiency, making them a favorable choice in hydraulic operations by significantly reducing operational costs and environmental impact. These pumps optimize energy consumption through their design, enabling efficient fluid movement with minimal energy expenditure. Recent studies indicate that vane pumps can consume 20% less energy compared to traditional pump systems. This efficiency not only lowers operational costs but also contributes to sustainability efforts by minimizing carbon footprints.

To extend the lifespan of rotary vane pump components, regular maintenance practices such as lubrication schedules are essential. Properly timed lubrication ensures that moving parts operate smoothly, reducing friction and subsequent wear. Identifying wear points early is crucial for proactive part replacement, which significantly minimizes downtime in operations. Regular inspections focusing on critical components like the rotor and vanes can help detect issues early, allowing for timely interventions.

Identifying and addressing common issues such as leaks and pressure drops in vane pumps is vital to maintaining their operational reliability. Leaks often result from worn seals, and checking these frequently can prevent extensive damage. For pressure drops, examining the pump's internal components like valves and chambers for obstructions or damage can resolve such problems. Guidelines for troubleshooting involve step-by-step checks of the pump's assembly, ensuring each part functions correctly to maintain optimal performance across various applications.