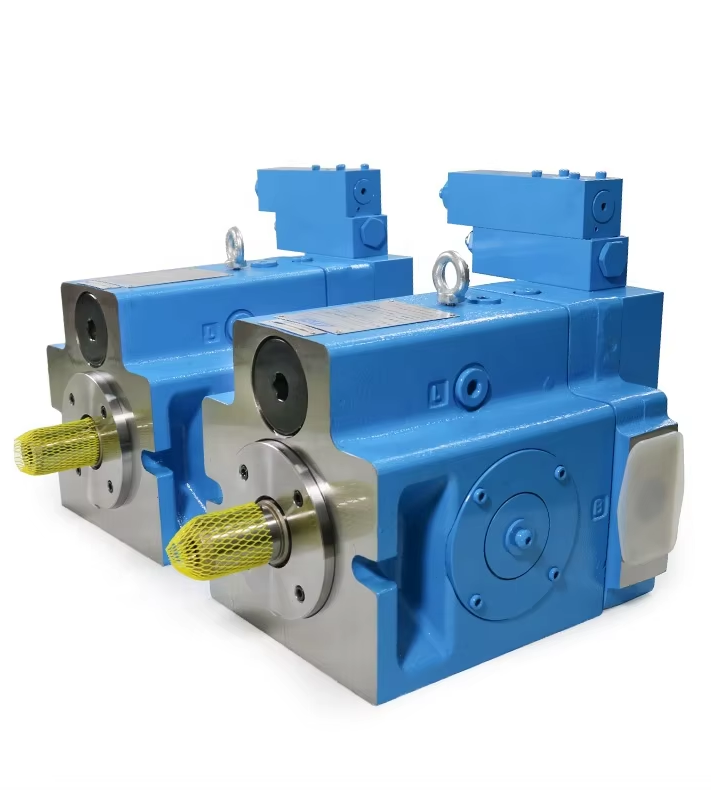

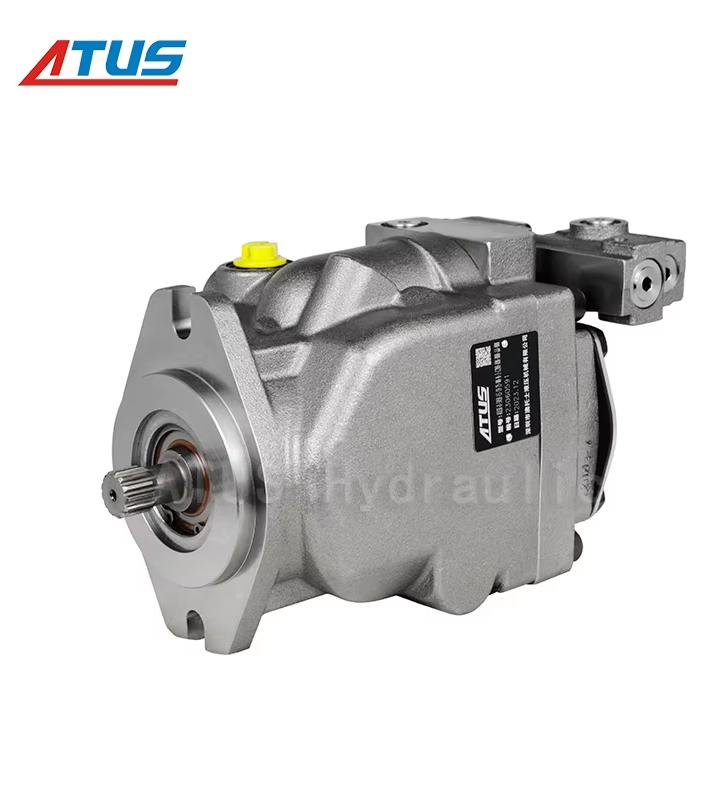

The ATUS Hydraulic Pump is a remarkable example of precision engineering, designed to deliver optimal performance in fluid power applications. This pump is manufactured using high-quality materials and advanced technology, ensuring it meets rigorous industry standards. Its robust construction allows the ATUS Hydraulic Pump to operate under extreme pressures while maintaining efficiency. The pump's design minimizes friction and energy loss, resulting in enhanced energy efficiency and reduced operating costs. Whether used in construction, manufacturing, or any heavy-duty application, the ATUS Hydraulic Pump provides reliable and consistent power, ensuring that machinery and equipment function seamlessly. Users can rely on ATUS for innovative solutions that enhance productivity and operational effectiveness.

With the ATUS hydraulic pump, the energy performance is improved, resulting in several energy savings, but higher efficiency is not needed. The latest designs of the ATUS pumps ensure that the energy waste owing to friction and unwanted resistances is kept to the minimum level possible, saving on operational costs in the long run. AT US also believes in environmental sustainability, providing that their hydraulic pumps comply with today’s energy standards while working towards a cleaner tomorrow. One of the strategies ATUS have employed to achieve this has been the use of variable speed drives which control the output of the pump to match specific requirements of the system Followed for better operational efficiency as well as energy saving. This in turn, puts unnecessary stress on the pump when maximum output is not required, hence avoiding energy waste and increasing the operational life of the pump. Further, ATUS hydraulic pumps are capable of working with different kinds of fluids including bio hydraulic fluids so that the customers have several options to choose from and bring down environmental impact. As industries transition to sustainable business models, ATUS has solutions for that as well as combine high performance with good efficiency to ensure businesses remain competitive while operating sustainably.

The management at ATUS is well aware of the fact that one industry cannot be the same with the other, and consequently it has a set of hydraulic pump solutions which are customizable for the clients. ATUS hydraulic pumps are designed for specific applications that may include customizing components such as the pressure rating or flow capacity or shocks. This versatility makes ATUS a great partner for various industries including agriculture and aerospace, and others requiring hydraulic pumps to enable appropriate operations. Clients are able to liaise with ATUS engineers and design pumps that suit their requirements; therefore, incorporation into the systems turned out to be smooth. Equally adjustable is the style of the materials and coatings used in manufacturing ATUS hydraulic pumps, options that improve the pump's performance against extreme temperatures, chemical effects, furcations etc. With this tailor-made strategy, ATUS makes sure that every hydraulic pump produced for a particular application can perform accurately as required without any changes. ATUS makes it possible for companies in any industry and of any size to improve the performance, reliability, and cost-effectivness of their hydraulic systems by providing such customizable solutions.

The safety of the operators and equipment is always a concern when designing and manufacturing any of ATUS hydraulic pumps. All products are designed keeping in mind safety as the number one priority and follow the industry rules, policies and guidelines. To protect the equipment and personnel, each ATUS hydraulic pump is put through thorough testing to ensure it works in a safe manner in all possible degrees. Such ATUS hydraulic pumps provide some built in safety features such as overpressure relief valves and overload safeties assuring the system is not operated outside of its safe limits. Given the fact that construction, manufacturing and aviation are some of the industries where safety requirements are very high, ATUS hydraulic pumps ensure that their systems are designed according to the latest norms. Customers can be kept informed of changes in safety regulations through ATUS's support when required so that they are able to remain compliant throughout the life of the pump. Helping businesses in reducing risks and making the workplace and the operations safer for the people in ATUS's number one priority.

ATUS hydraulic pumps are designed with consistency that lasts, making them suitable for nearly all sectors of industry. ATUS pumps are made to perform even in the most stressful situations, which to be consistent and dependable. Used on large industrial or valuable agricultural machines, ATUS hydraulic pumps operate with variety of fluid power rather efficiently. Accurate fluid power control or management is one of the dominating features of ATUS hydraulic pumps due to their high degree of efficiency which is most useful in applications that require high precision in measurement and fluid management. The high pressure cut-off and low pressure cut-off components are machined and fabricated to great levels, enabling the pumps to operate smoothly despite minor fluctuations of flow and pressure. This in turn yields improved output consistency, coordinating productivity and minimizing the wear of systems that are connected. ATUS pumps also include reliability as one of the dependable attributes, which decreases the chances of failures and frequent breakdowns. Efficiency, as well as care comes with these robust materials which allows business activities to be more productive, saving time and money in the long run.

Shenzhen Aotoshi Hydraulic Machinery Co., Ltd. is a comprehensive hydraulic service enterprise integrating the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors and valves. Its products and technologies are widely used in various industries such as mining machinery, marine machinery, construction machinery, power plant equipment, injection molding machines, die-casting machines, steel mills, etc., hydraulic system engineering transformation, hydraulic system upgrade optimization, energy-saving and speed-up transformation.

Delivers consistent flow rates for optimized performance.

Built to withstand harsh environments and heavy use.

Suitable for various fluids including lubricants and fuels.

Designed for extended operation with minimal service needs.

Yes, David. The ATUS Hydraulic Pump is designed for continuous heavy-duty operations, ensuring consistent performance even under high-demand conditions in industrial settings.

Hi Elena, the ATUS Hydraulic Pump is compatible with most standard hydraulic systems and can be easily integrated without the need for special modifications.

Hello Michael, the ATUS Hydraulic Pump can handle high-pressure ratings of up to 350 bar, making it ideal for a wide range of industrial applications.

Hello Chen, regular maintenance is recommended every 6 to 12 months, depending on usage intensity, but the ATUS Hydraulic Pump is designed to minimize the need for frequent servicing.

Hi Pierre, the ATUS Hydraulic Pump is built to perform well in extreme temperatures, including cold environments, ensuring reliable operation in diverse conditions.