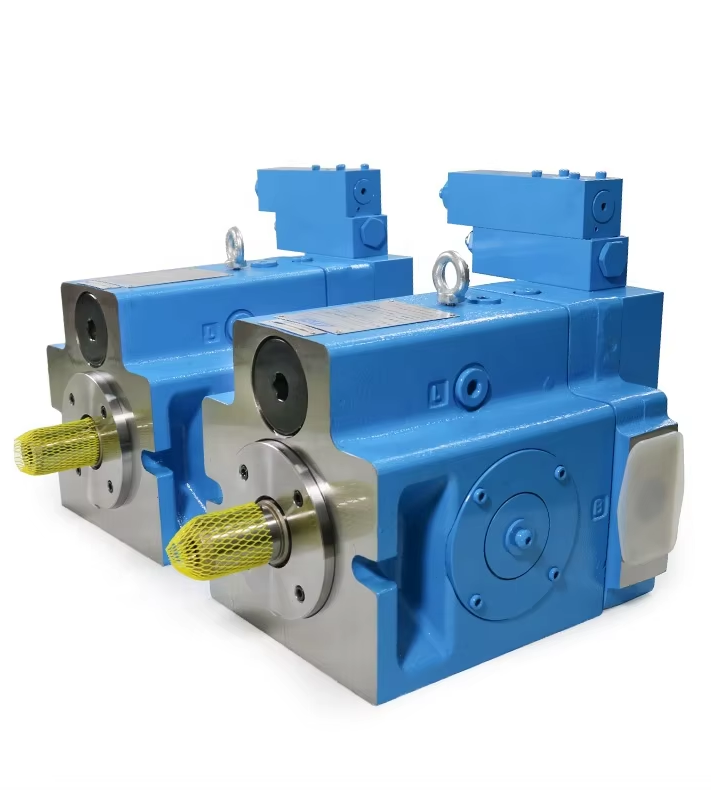

Aotuoshi Hydraulic offers comprehensive hydraulic pump solutions that cover all your needs. From 12 volt electric hydraulic pumps and 12v hydraulic pump units to 2 stage pump hydraulic systems, air hydraulic pumps, air over hydraulic pumps, belt drive and belt driven hydraulic pumps, cat hydraulic pumps, and danfoss hydraulic pump alternatives, we have a wide range of products. Our pumps are designed and manufactured with precision, using the latest technology and the best materials. We focus on providing reliable, efficient, and durable hydraulic pump solutions for various industries. Whether you're in manufacturing, construction, or any other field that requires hydraulic power, Aotuoshi Hydraulic has the right pump for you.

Our air hydraulic pumps at Aotuoshi Hydraulic redefine industry standards. These pumps offer excellent power - to - weight ratios and are highly resistant to harsh environments. Through strategic partnerships, we supply top - tier air hydraulic pumps globally, driving business growth for our B2B partners.

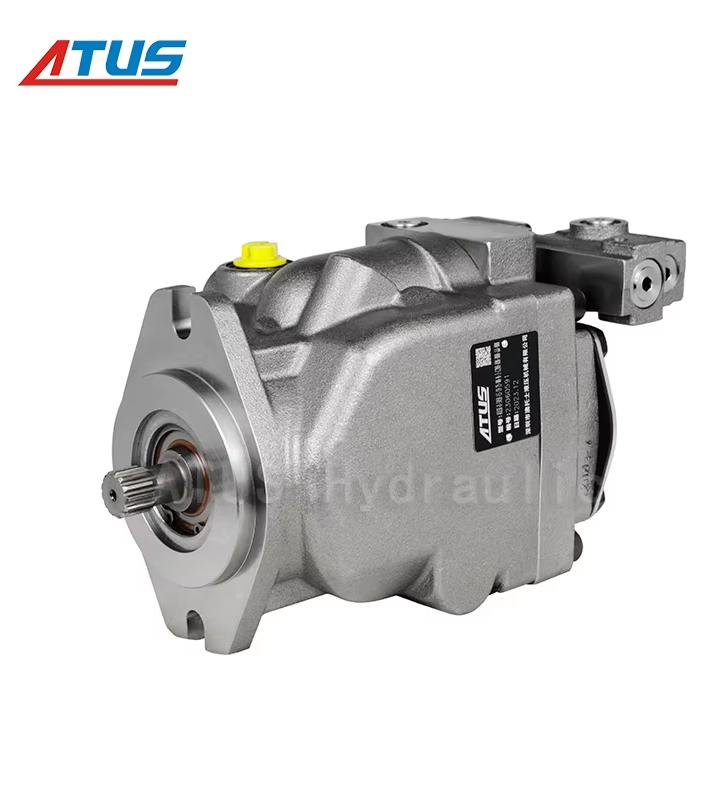

Aotuoshi Hydraulic’s 12 volt electric hydraulic pump stands out for its reliability and efficiency. Engineered with advanced technology, this pump delivers consistent performance across various industrial applications. As a leading B2B provider, Aotuoshi Hydraulic ensures each product meets strict quality standards, offering customized solutions to partners worldwide.

Our belt driven hydraulic pumps showcase Aotuoshi Hydraulic’s commitment to quality. Each pump undergoes rigorous testing to ensure durability and reliability. As a B2B - focused company, we offer OEM services, enabling businesses to customize products according to their specific requirements.

Aotuoshi Hydraulic’s hydraulic pumps match the performance of leading brands. Our danfoss - equivalent pumps provide exceptional functionality at competitive costs. We offer comprehensive after - sales support, ensuring long - term satisfaction for our B2B partners.

Shenzhen Aotoshi Hydraulic Machinery Co., Ltd. is a comprehensive hydraulic service enterprise integrating the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors and valves. Its products and technologies are widely used in various industries such as mining machinery, marine machinery, construction machinery, power plant equipment, injection molding machines, die-casting machines, steel mills, etc., hydraulic system engineering transformation, hydraulic system upgrade optimization, energy-saving and speed-up transformation.

Delivers consistent flow rates for optimized performance.

Built to withstand harsh environments and heavy use.

Suitable for various fluids including lubricants and fuels.

Designed for extended operation with minimal service needs.

Our 12 volt electric hydraulic pump features advanced technology for consistent performance, compact design, and high efficiency, making it suitable for a wide range of applications.

Yes, our air hydraulic pumps are highly resistant to harsh conditions, offering excellent power - to - weight ratios and reliable operation.

Absolutely. As a B2B - oriented company, we provide OEM services for belt drive hydraulic pumps to meet specific business needs.

Our 2 stage pump hydraulic systems are designed to maximize productivity with variable flow and pressure, adapting well to different workloads.

We offer comprehensive after - sales support, including technical assistance, maintenance guidance, and prompt replacement parts supply.

Our pumps are engineered to be compatible with a wide range of industrial machinery, ensuring seamless integration.

Our danfoss - equivalent hydraulic pumps are built with high - quality materials and undergo strict testing, ensuring a long and reliable lifespan.